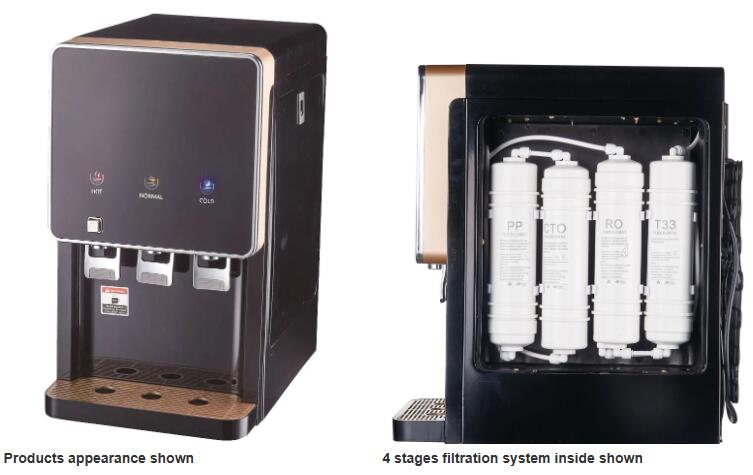

Hot and cold tabletop water dispenser with UF or RO purification system

Products quick details as following:

POU table top water dispenser With Child lock

-Product model: PT-1417T

-Products dimension: L 480 x W 295 x H 520(mm)

_Function: Hot&Cold&Warm,

_Heating Power/Capacity: 420W/5L/h,85-95 ℃

_Compressor Cooling power/Capacity: 90W/2L/h,6-10 ℃

_Related Voltage/Frequence: 220-240V~50/60hz

_Packing(mm)L*W*H: 505*325*550mm

_Logo printing: OEM

_Product Color: Goldern and Black

_Body material: top front panel is glass material, top silver plating frame, painting goldern drip tray, the other front panel with brand new ABS painting black

_Side plates: Galvanized iron sheet

_Compressor brand: ARNOLDAN

_Water tank: SS304 Welding tank with food grade silicone tube

_Water tank volume: Hot/Cold 1.5/3.2L

-Pipe in system

Products features

This machine is a fully automatic drinking water machine. After installation, the user only needs to open the water source switch to realize the automatic water production function. Pls make sure that there is pure water source supply before installation.

Main Technical Parameters

Rated Voltage /frequency:220-240 V~50/60 Hz

Electric shock resistance:Ⅰ

Rated Power:510 W

Rated Heating Power:420 W

Rated Cooling Power:90 W

Inlet Water Pressure:0.1—0.4 Mpa

Cooling Capacity:≤10℃,2L/h

Heating Capacity:≥90℃, 5L/h

Proper temperature:10℃—43℃

Power consumption:1.5kW·h/24h

Freezing Medium:R134a/32g

Climate Type:T

Water/Temperature:Municipal water /5—38℃

Relative humidity :≤90%

Installation, Commissioning and Use

.The installation method of this machine should be selected according to the actual situation in your kitchen. The host can be placed around the wall about 15cm, as shown in the figure below (pictured); the installed room should have floor drain. ★Installation 1. First check the inlet water pressure. If the inlet pressure is greater than 0.4Mpa, a pressure reducing valve must be installed at the pipeline position.

2. Prepare the necessary installation tools and installed accessories, determine the installation location; install the three way valve, and the main unit. 3. Install the PE pipe in the following parts according to the process flow: (Figure 3) ★Commissioning and Use 1. Pipeline inspection: After the machine has been producing water for 30 minutes, check the parts and pipelines for water leakage and water seepage.

2. Finish the pipeline: organize and fix the various installation pipelines, and then clean the installation site.

3. This machine is controlled by the opening and closing of the mechanical float valve. Normal use is as convenient and safe as using tap water.

4. Open the water ball valve, the straight drink machine starts to produce water, plug the plug into the 220V ~ 50/ 60Hz power supply, at this time the power light is on, and the hot water tap can release the water before the heating switch and the refrigeration switch can be turned on. After the heating switch is turned on, the red light is on and the heating starts. When the red light is off, the heating is completed. At this time, the water temperature is above 90 °C, and hot water is available. Turn on the cooling switch, the blue light is on, and the cooling water starts. When the water temperature is less than 8 °C, the blue light is off to indicate that the cooling is completed and the cold water is available.

Write your message here and send it to us